Hardware

This section will show you all the steps involved in the mechanical assembly of the ROV. 3D-printing parts, cutting out and modifying frame parts and motors etc. If you are adventurous or want to modify the ROV yourself, these steps are more flexfible than for example the electronics section for custom solutions.

If some of these steps require skills you don't have or methods you don't know, this tutorial will not go into detail to teach those. But the internet is full of good tutorials, and I will try to link to relevant resources where I know a good one.

3D-printing parts

Components

-

4 x propellers

-

4 x propeller guards

-

4 x propeller guard grids

-

2 x motor mounts

Tools

-

3D printer

-

All regular filament materials should work

-

Procedure

Brand and type of 3D-printer does not matter, as long as it produces waterproof parts that are somewhat rigid. I have been using PLA as a material with good results. If you don't have an Onshape account, or want to set one up, you can download the .stl files from our GitHub. Link here, download the .zip folder called "eduROV_production_files.zip".

Printer settings depends on you printer and material, but orientation and use of support is quite important for print quality. Make sure the propellers are rotated as shown in the pictures here, all the other parts can be printed flat as they are imported by default. Use the support option "only from build plate" if that is available in your slicer as it will give the best surface finish possible on the propellers. We suggest using an infill of around 15-20%, as it is a nice balance between stiffness and use of material.

Post processing is only necessary to clean off uneven edges and such.

Cutting the boards

Components

-

Cutting board

-

Cutting templates

-

Three different sizes

-

Tools

-

Drill

-

19mm spade bit

-

5mm drill bit

-

7mm drill bit

-

Jigsaw

-

Utility knife

-

Glue gun

-

Clamps

Nice to have:

-

Center punch

Procedure

Start by printing out the cutting templates, make sure these are not scaled. Check the scale by measuring on the printed paper that the dimensions written on the document is correct. Cut these to shape so they just fit on top of the three different sized cutting boards, and glue them down with some tacks of hot-glue. It's a good idea to place the glue-dots in such a way that the template stays in place as you work on cutting out the shapes.

Mark and drill all the holes that should be drilled, I also like to mark and drill the corners of the areas that are to be cut away, so the jigsaw blade has some space to turn.

To cut out the shapes of the plates, clamp the workpieces to the edge or corner of a solid workbench or table. If it becomes to unstable or wobly, reclamp it rather than breaking something.

Cutting pipes and modifying motors

Components

-

1 length of 19mm plastic tubing

-

4 x 12V bilge pumps

Tools

-

Drill

-

Hobby saw

-

Utility knife

-

Clamps

-

Ruler/calipers/tape measure

Nice to have:

-

Pipe cutter

-

Bench vice

Procedure

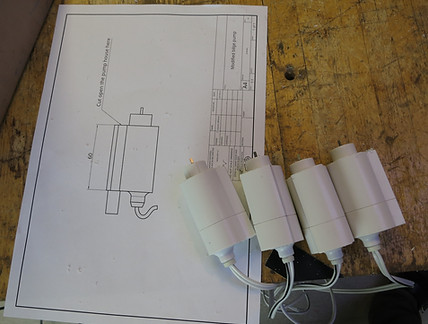

The cutting templates for these parts is mostly there to provide the neccesary measurements. The pictures above shows how the parts are supposed to look when they are finished. When cutting open the motors, you have to work your way around the outter shell in order to avoid cutting open the plastic on the inside.

If you have a pair of calipers, it is a good idea to use them to score a cutting line all the way around the motor.

Assembling the frame

Components

-

Modified motors

-

Printed motor mounts

-

Horisontal plate

-

Vertical plates (legs)

-

Pre-cut plastic tubes

Tools

-

Hot glue gun

-

90 degree angle

Procedure

This step is mostly a quite straight forward jigsaw puzzle. Assemble the parts as shown in the pictures and aply generous amounts of glue to hold them together. It's a good idea to use a 90 degree angle to make sure the legs turn out perfectly perpendicular to the main plate.

Electronics mounting board and hull preparation

Components

-

Pre-cut parts for the mounting board

-

Pre-cut short pieces of tubing

-

Waterproof box

-

eduROV Motherboard

-

Battery

-

Raspberry Pi camera

Tools

-

Hot glue gun

-

Permanent marker

Procedure

The two small square pieces of cutting board you made earlier, should be glued in place in the remainding part of the board as shown in the picture above. Make sure the orientation of the board is right!. These small pieces serve as restraining guides for the battery in the box. We will mount the Raspberry Pi on the other side later.

The last little piece of cutting board you made can be used to support the Pi camera in the groove on the front of the board. Make sure it is flush with the top-side of the plate and that the ribbon cable exits downwards.

Dry fit everything as you go along to make sure that it all fits where it is supposed to without fragile parts bumping into anything.

Inserting wire-throughs

Components

-

Waterproof box

-

3 x small pre-cut plastic tubes

-

1 rubber hose

-

ca 10cm

-

Tools

-

Drill

-

19mm spade drill bit

-

9mm drill bit

-

Hot glue gun

-

Permanent marker

-

Sand paper - semi rough (120-180 grit)

-

Hot-air gun

Procedure

Measure up and mark positions for the holes, then glue the tubes and rubber hose in place. It is a good idea to roughen up the surfaces first with some sand-paper to make the glue grip extra well. I also raised the waterproof box a little from the table so most of the small tubes mostly stick out on the underside of the box. Make sure the hot-glue forms a smooth surface on both sides of the box and connect well between the tubes and the box. This joint needs to be water-proof!

Mounting propellers

Components

-

Mostly finished eduROV

-

4 x propellers

-

4 x propeller guards

-

4 x propeller guard grids

-

Tools

-

Glue gun

-

Zip ties

-

Utility knife

Procedure

Start by cleaning up the edges of all the 3D-printed parts with the utility knife, then mount the last two motors with hot-glue and add the propeller guards to the assembly. Simply press the propellers onto the motor axles, and zip-tie the protection grid over the whole thing. Make sure the propellers spin freely after you have pressed them on!

It's now time to charge the battery and see if everything works!

Waterproofing the hull

Components

-

Finished ROV

Tools

-

Glue gun

-

Hot-air gun

-

Lip-balm/vaseline or similar

Nice to have

-

Vacuum pump with manometer

Procedure

This step is a testing and verification step. We don't want all our work to be for nothing if the electronics get fried by water entering the system of our ROV. There are two main steps to the waterproofing; 1) a clean and slightly greased rubber gasket around the edge of the hull and 2) smooth and tight glue-joints around the wire-throughs.

You can smooth out the hot-glue joints with the hot-air gun, just don't melt the wire insulation. Go slow and steady to smooth it out, and check on a somewhat regular basis using a vacuum-pump (if you have one) that the hull can hold a negative pressure. This way we simulate an external pressure of water as the ROV dives. Waterpressure increases with 1 bar pr 10 meters you dive. Cheap vacuum pumps can typically reach 0.7-0.8 bar vacuum, giving us a verified diving depth of roughy 8 meters.

Tuning bouancy

According to the Onshape assembly analysis. The total volume of the ROV is approximately 2.7 litres. In order to attain neutral bouancy, meaning that it does not sink or rise by itself in the water, it needs to weigh the same as the water it supresses. Our aim is therefore to reach a total weight of the ROV (on land) of about 2.7kg. This is fine-tuned when you place the ROV in water for the first time anyway, just remember to bring some extra zip ties and metal plates.

Design files

In order to be fully transparent and open-source, we have used Onshape* to design the mechanical structures making up the ROV. Find the project files by clicking the link below, or searching for "eduROV_development_version" in Onshape. Updates may take place at some point, in that case the links here will be updated as well.

*Onshape is a free-access browser based CAD system. It's free to make a user, although you will have to pay them to keep your project files hidden. (no issue for us)